categorias

AR COMPRIMIDO > Compressores de ar

AR COMPRIMIDO > Reservatórios de ar comprimido

AR COMPRIMIDO > Redes de ar comprimido em alumínio

AR COMPRIMIDO > Purgadores automáticos

AR COMPRIMIDO > Tratamento de condensado

AR COMPRIMIDO > Elementos filtrantes premium

AR COMPRIMIDO > Materiais Adsorvedores / Absorvedores

AR COMPRIMIDO > Geradores de nitrogênio on site

AR COMPRIMIDO > Geradores de oxigênio on site

Perguntas Frequentes sobre Ar comprimido

Produtos

Ar comprimido

Compressores de Ar

- Compressor de parafuso | Rotor Plus (4 a 25 hp)

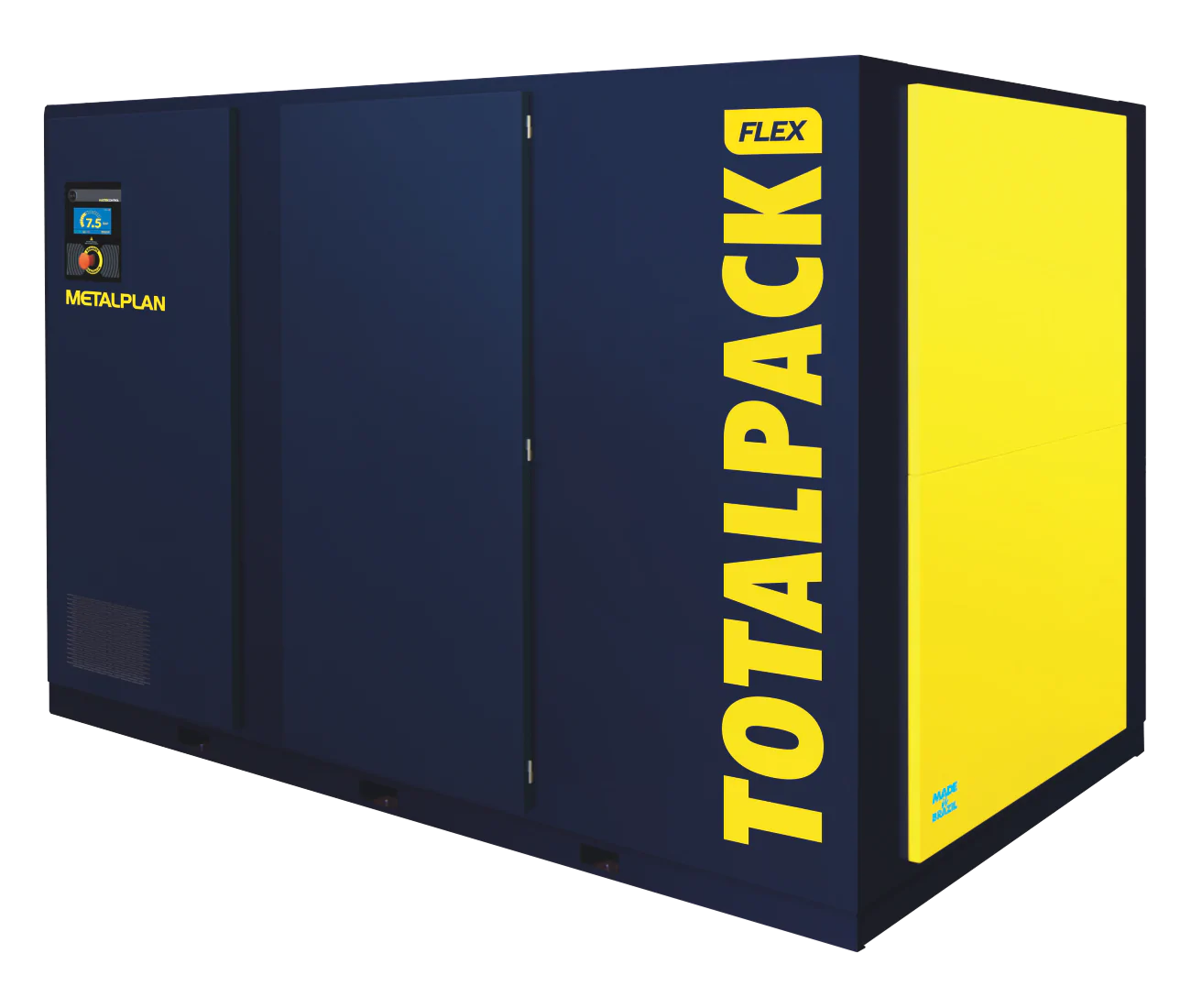

- Compressor de parafuso | TotalPack Flex (10 a 250 hp)

- Compressor isento de óleo (scroll) | ScrollTech Zero Oil Free (5 a 50 hp)

- BOOSTER ISENTO DE ÓLEO (PISTÃO)/COMPRESSOR DE ALTA PRESSÃO (ATÉ 40 BAR)

- BOOSTER LUBRIFICADO (PISTÃO)/COMPRESSOR DE ALTA PRESSÃO (ATÉ 40 BAR)

Secadores de ar comprimido

- Secadores por absorção | DewDrop (6 a 32 pcm)

- Secador por refrigeração com filtros integrados | Titan Plus (20* a 250 pcm)

- Secador por refrigeração com filtros integrados | Energy Plus (250 a 9600 pcm)

- Secador por adsorção | Hybrid (15 a 20000 pcm)

Filtros e purificadores

- Filtros coalescentes, adsorvedores e microbiológicos | Hyperfilter

- Módulo ISO Classe Zero / ar isento de óleo | ModuCarb

- Ar comprimido para respiração humana | Inspire

- Purificador de ar comprimido odontológico | Dental Air Purifier

Reservatórios de ar comprimido

Redes de ar comprimido em alumínio

Purgadores automáticos

- Purgador eletrônico digital temporizado | Cronomatic

- Purgador magnético de bóia | Zeromatic

- Dreno pescador | Easy Drain

Tratamento de condensado

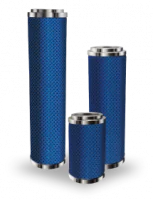

Elementos filtrantes premium

Lubrificantes

- Óleo 100% sintético para compressores de ar | Rotor Oil Extra EcoBlue

- Óleo 100% sintético FOOD GRADE para compressores de ar | Rotor Oil Extra Food Grade

Materiais adsorvedores / absorvedores

Ar comprimido

Geradores de nitrogênio on site

- Gerador de nitrogênio gasoso on site (industrial) | NitroMax

- Gerador de nitrogênio gasoso on site (automotivo) | NitroMax Tyre

Geradores de oxigênio on site

- Gerador de oxigênio gasoso on site (industrial) | OxiPlus

- Gerador de oxigênio gasoso on site (hospitalar) | OxiPlus Med

REFRIGERAÇÃO INDUSTRIAL

BIOGÁS & GNV

- COMPRESSOR DE PARAFUSO LUBRIFICADO PARA BIOGÁS | POWERPACK | ATÉ 3000 M³/H

- COMPRESSOR DE PISTÃO COM OU SEM LUBRIFICAÇÃO PARA BIOMETANO | DA 300 M | ATÉ 6000 M³/H

- COMPRESSOR DE PISTÃO COM OU SEM LUBRIFICAÇÃO PARA BIOMETANO/GNV | SA 200 M | ATÉ 6000 M³/H

- ESTAÇÃO INTEGRADA DE COMPRESSÃO & PURIFICAÇÃO | UPGRADING DE BIOGÁS EM BIOMETANO

entre em contato

R. Fernão Dias, 14 – Cajamar – São Paulo –

Brasil – 07790-560

Telefone: +55 11 4448-6900

E-mail: metalplan@metalplan.com.br

Segunda a Quinta, das 8 às 18h. Sexta, das 8 às 17h.

redes sociais

Todos os direitos reservados | Política de privacidade

Desenvolvido por Agência Tipo