O compressor de parafuso

líder em vendas e desempenho

- Silencioso

- Baixo consumo de energia

- Menor custo de manutenção

- 4 a 25 hp

aguardamos seu contato

aguardamos seu contato

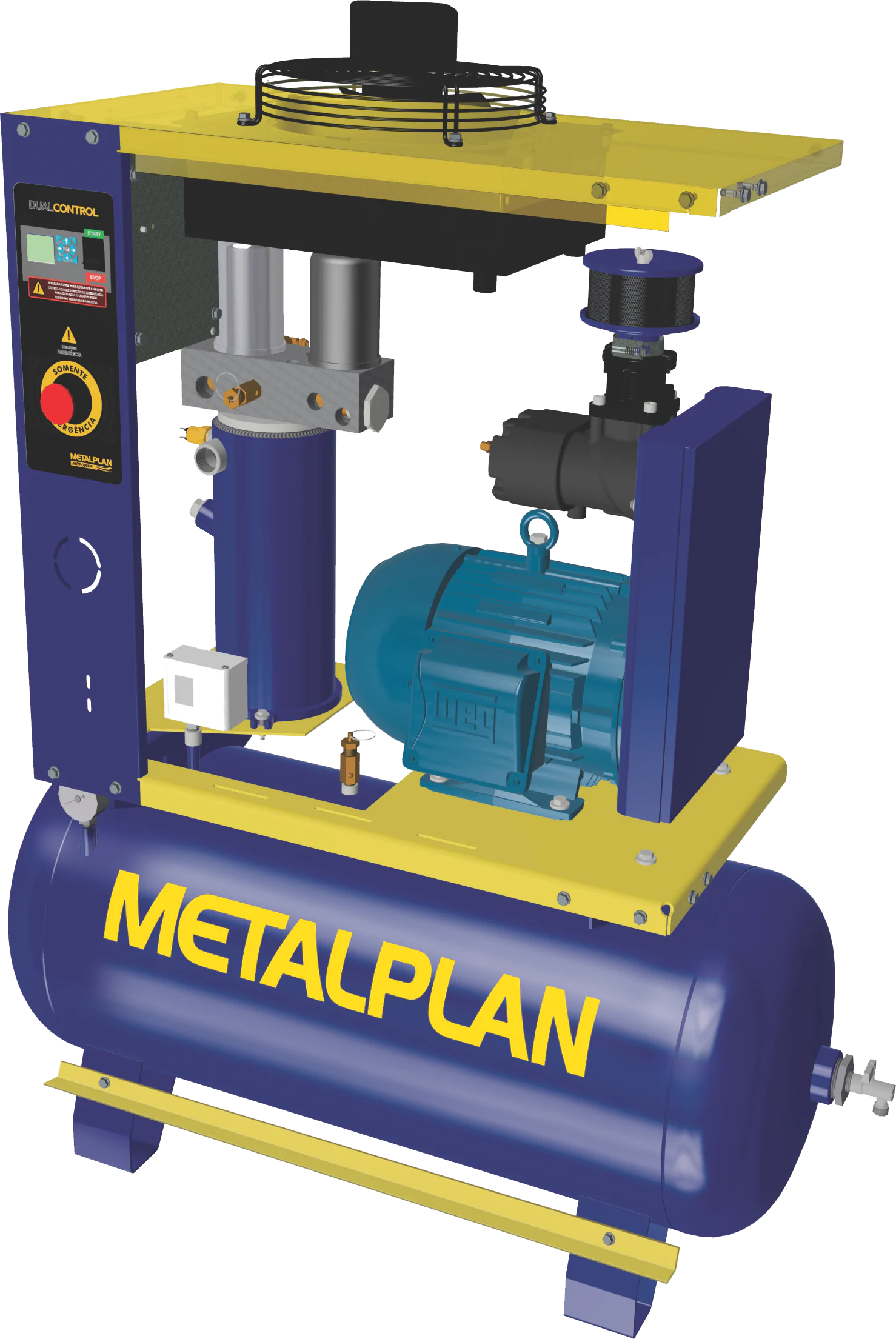

Compressor de Ar de Parafuso | Rotor Plus (4 a 25 Hp)

O compressor de parafuso líder em vendas e desempenho

O compressor de parafuso Rotor Plus é pioneiro na tecnologia rotary screw para pequenas e médias vazões, tornando-se a principal referência do mercado e o mais vendido no país até 25 hp.

Este equipamento proporciona ganhos significativos em produtividade e economia, em substituição aos obsoletos compressores de pistão.

O consumo energético 50% menor e o custo de manutenção 70% mais baixo tornam o Rotor Plus 60% mais econômico que qualquer compressor de pistão ao longo do tempo.

Desta forma, o retorno do seu investimento é rápido, geralmente em até seis meses, de acordo com a utilização.

A economia proporcionada pelo compressor de parafuso Rotor Plus com relação a um equipamento similar de pistão pode chegar ao valor de um Mustang zero km, cerca de R$ 500 mil, num período de 48 mil horas de uso (confira o comparativo no catálogo abaixo).

Outra vantagem é a vazão real igual à teórica. Isso significa funcionamento com 100% da capacidade em tempo integral, enquanto nos compressores de pistão a vazão real é 30% menor.

O lubrificante sintético Rotor Oil Extra Ecoblue proporciona performance eficiente por 8 mil horas, duração 40 vezes superior à dos equipamentos de pistão, que demandam trocas de óleo a cada 200 horas.

O compressor Rotor Plus tem baixo nível de ruído e vibração zero. Conta com o Easy Drain, dreno manual acessível, que simplifica a drenagem em locais de difícil acesso. A facilidade de integração a reservatório, secador e filtros é mais um diferencial do equipamento.

Todas essas vantagens incorporam o DNA Metalplan, o primeiro fabricante de compressores do mundo certificado ISO 50001 – Gestão de Energia.

Com quatro décadas de expertise, nossa missão é tornar acessíveis a inovação tecnológica e a eficiência energética, através de projetos inteligentes e da fabricação Made in Brazil, possibilitando financiamento via FINAME/BNDES.

A mais completa rede de assistência técnica autorizada do mercado reúne mais de 70 unidades e 200 técnicos altamente qualificados por todo o país.

A confiabilidade e robustez dos compressores Metalplan é atestada por empresas de todos os portes, no Brasil e mais de 20 países para onde exportamos, incluindo os Estados Unidos.

Entre em contato com nossos especialistas e garanta as melhores soluções em ar comprimido para o seu negócio!

- 60% + econômico do que qualquer compressor de pistão

- Vazão teórica = vazão real. Não há perdas na compressão

- Ultra silencioso: ruído 80% inferior ao compressor de pistão

- Custo de manutenção 70% inferior ao compressor de pistão

- Vibração zero

- Easy Drain: dreno manual acessível

- Quadro elétrico completo

- Geração Lego: reservatório, secador e filtros integráveis

- Óleo sintético: 8000 horas.

- Painel microprocessado.

- Sistema Dual Control, liga e desliga o compressor de maneira inteligente, respeitando a oscilação da demanda de ar comprimido

- Fabricado no Brasil, com financiamento FINAME/BNDES

- Mais de 70 oficinas autorizadas em todo o país

- Potências de 4 a 25 hp.

- Conheça também a versão Rotor Plus Laser: alta pressão, especialmente projetado para corte a laser.

A mais completa rede de assistência técnica autorizada do mercado reúne mais de 70 unidades e 200 técnicos altamente qualificados por todo o país.

A confiabilidade e robustez dos compressores Metalplan é atestada por empresas de todos os portes, no Brasil e mais de 20 países para onde exportamos, incluindo os Estados Unidos.

Entre em contato com nossos especialistas e garanta as melhores soluções em ar comprimido para o seu negócio!

- 60% + econômico do que qualquer compressor de pistão

- Vazão teórica = vazão real. Não há perdas na compressão

- Ultra silencioso: ruído 80% inferior ao compressor de pistão

- Custo de manutenção 70% inferior ao compressor de pistão

- Vibração zero

- Easy Drain: dreno manual acessível

- Quadro elétrico completo

- Geração Lego: reservatório, secador e filtros integráveis

- Óleo sintético: 8000 horas.

- Painel microprocessado.

- Sistema Dual Control, liga e desliga o compressor de maneira inteligente, respeitando a oscilação da demanda de ar comprimido

- Fabricado no Brasil, com financiamento FINAME/BNDES

- Mais de 70 oficinas autorizadas em todo o país

- Potências de 4 a 25 hp.

- Conheça também a versão Rotor Plus Laser: alta pressão, especialmente projetado para corte a laser.

O compressor de ar de parafuso Rotor Plus é um equipamento projetado para oferecer máxima eficiência e desempenho em diversas aplicações que exigem ar comprimido.

Com potências de 4 a 25 hp, este compressor se destaca no mercado brasileiro, sendo um dos modelos mais vendidos. Ele também conta com a versão Laser, um compressor de alta pressão especialmente projetado para corte a laser.

Pioneiro na tecnologia rotary screw para pequenas e médias vazões, o Rotor Plus permite uma compressão mais eficiente e silenciosa.

O Rotor Plus se diferencia dos tradicionais compressores de pistão, proporcionando economia significativa de energia e manutenção.

Com um design moderno e funcional, é a escolha perfeita para quem busca qualidade e desempenho.

Benefícios

A utilização do compressor de ar parafuso Rotor Plus traz uma série de benefícios que o tornam uma excelente opção para indústrias e empresas de diversos segmentos:

- Seu consumo energético é até 50% menor em comparação aos compressores de pistão.

- O custo de manutenção é até 70% menor, permitindo que as empresas economizem ainda mais a longo prazo.

- A durabilidade do lubrificante sintético, que pode chegar a 8.000 horas de uso, muito superior ao dos compressores de pistão.

- O Rotor Plus também oferece um nível de ruído extremamente baixo, comparado aos compressores pistão.

Aplicações

Por ser um equipamento versátil, o compressor de parafuso Rotor Plus pode ser utilizado em diversas aplicações.

Ele é ideal para empresas que necessitam de ar comprimido de forma constante e eficiente, como indústrias de diversos segmentos, oficinas, centros automotivos, transportadoras, gráficas, marcenarias, serviços de pintura em geral, consultórios odontológicos, clínicas e hospitais, entre outros.

A facilidade de integração ao reservatório, secador e filtros torna o Rotor Plus uma escolha prática para qualquer instalação.

Vantagens e Economia

Uma das maiores vantagens do compressor de ar de parafuso Rotor Plus é a sua eficiência energética.

O retorno sobre o investimento pode ser alcançado em até seis meses, dependendo da utilização, o que representa uma excelente oportunidade de redução de custos operacionais.

A economia acumulada em 48 mil horas de uso pode equivaler ao valor de um carro novo, evidenciando a rentabilidade deste equipamento.

A vazão real do Rotor Plus é igual à teórica, garantindo funcionamento com 100% da capacidade em tempo integral.

Isso se traduz em um desempenho consistente e em uma maior produtividade para os usuários, que podem contar com um ar comprimido de alta qualidade.

Facilidade de Utilização

O projeto do compressor de ar de parafuso Rotor Plus foi desenvolvido para que o equipamento seja fácil de operar.

O painel micro processado permite um monitoramento simples das operações e a implementação de controles inteligentes, como o Sistema Dual Control, que ajusta automaticamente o funcionamento do compressor conforme a demanda de ar comprimido.

O Easy Drain, dreno manual acessível, simplifica a drenagem do compressor, mesmo em locais de difícil acesso.

Além disso, possui quadro elétrico completo.

Perguntas Frequentes sobre: Compressor de Ar de Parafuso

nossos engenheiros

aguardam seu contato

nossos engenheiros

aguardam seu contato

Produtos

Ar comprimido

Compressores de Ar

- Compressor de parafuso | Rotor Plus (4 a 25 hp)

- Compressor de parafuso | TotalPack Flex (10 a 250 hp)

- Compressor isento de óleo (scroll) | ScrollTech Zero Oil Free (5 a 50 hp)

- BOOSTER ISENTO DE ÓLEO (PISTÃO)/COMPRESSOR DE ALTA PRESSÃO (ATÉ 40 BAR)

- BOOSTER LUBRIFICADO (PISTÃO)/COMPRESSOR DE ALTA PRESSÃO (ATÉ 40 BAR)

- Gerenciamento eletrônico de compressores

Secadores de ar comprimido

- Secadores por absorção | DewDrop (6 a 32 pcm)

- Secador por refrigeração com filtros integrados | Titan Plus (20* a 250 pcm)

- Secador por refrigeração com filtros integrados | Energy Plus (250 a 9600 pcm)

- Secador por adsorção | Hybrid (15 a 20000 pcm)

Filtros e purificadores

- Filtros coalescentes, adsorvedores e microbiológicos | Hyperfilter

- Módulo ISO Classe Zero / ar isento de óleo | ModuCarb

- Ar comprimido para respiração humana | Inspire

- Purificador de ar comprimido odontológico | Dental Air Purifier

Reservatórios de ar comprimido

Redes de ar comprimido em alumínio

Purgadores automáticos

- Purgador eletrônico digital temporizado | Cronomatic

- Purgador magnético de bóia | Zeromatic

- Dreno pescador | Easy Drain

Tratamento de condensado

Elementos filtrantes premium

Lubrificantes

- Óleo 100% sintético para compressores de ar | Rotor Oil Extra EcoBlue

- Óleo 100% sintético FOOD GRADE para compressores de ar | Rotor Oil Extra Food Grade

Materiais adsorvedores / absorvedores

ar comprimido

Geradores de nitrogênio on site

- Gerador de nitrogênio gasoso on site (industrial) | NitroMax

- Gerador de nitrogênio gasoso on site (automotivo) | NitroMax Tyre

Geradores de oxigênio on site

- Gerador de oxigênio gasoso on site (industrial) | OxiPlus

- Gerador de oxigênio gasoso on site (hospitalar) | OxiPlus Med

REFRIGERAÇÃO INDUSTRIAL

BIOGÁS & GNV

- COMPRESSOR DE PARAFUSO LUBRIFICADO PARA BIOGÁS | POWERPACK | ATÉ 3000 M³/H

- COMPRESSOR DE PISTÃO COM OU SEM LUBRIFICAÇÃO PARA BIOMETANO | DA 300 M | ATÉ 6000 M³/H

- COMPRESSOR DE PISTÃO COM OU SEM LUBRIFICAÇÃO PARA BIOMETANO/GNV | SA 200 M | ATÉ 6000 M³/H

- ESTAÇÃO INTEGRADA DE COMPRESSÃO & PURIFICAÇÃO | UPGRADING DE BIOGÁS EM BIOMETANO

entre em contato

R. Fernão Dias, 14 – Cajamar – São Paulo –

Brasil – 07790-560

Telefone: +55 11 4448-6900

E-mail: metalplan@metalplan.com.br

Horário de Atendimento

Segunda a quinta-feira: 8h às 18h

Sexta-feira: 8h às 17h

Horário de Expedição (Coletas por Transportadoras)

Segunda a quinta-feira: 8h às 16h45

Sexta-feira: 8h às 15h45

Intervalo para almoço: das 11h20 às 12h40

redes sociais

Todos os direitos reservados | Política de privacidade

Desenvolvido por Agência de Marketing B2B e Marketing Industrial