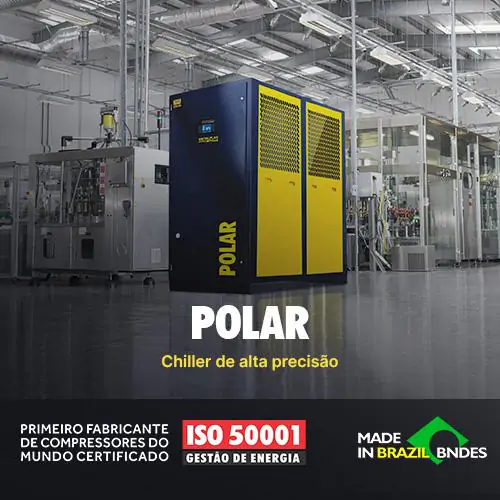

Polar

Chiller de alta precisão

- Água gelada com precisão de 0,1°C

- Maior produtividade para o seu processo

- 1.000 a 720.000 kcal

aguardamos seu contato

aguardamos seu contato

Chiller de Água Gelada e Outros Fluidos | Polar

O chiller é um equipamento indispensável para processos industriais que exigem controle preciso de temperatura.

Dispositivos como o chiller de água gelada industrial garantem eficiência e estabilidade em operações de resfriamento, seja para máquinas, moldes ou produtos finais.

O chiller resfriador Polar da Metalplan é reconhecido pela sua flexibilidade e desempenho em diferentes cenários, desde linhas de produção de plástico até indústrias alimentícias, oferecendo alta confiabilidade e robustez no resfriamento de água e outros fluidos, com projeto dimensionado para operação contínua e ambientes industriais adversos.

Sua aplicação proporciona maior produtividade e proteção aos equipamentos, evitando problemas como superaquecimento.

Enquanto termorreguladores, dry coolers e termo-chillers têm utilização limitada a algumas aplicações, o chiller Polar é ideal para os mais variados serviços, como: termoformagem, corte e solda, laminação, extrusão de tubo, extrusão de chapas, flexografia, sopro, extrusão de balão e injeção.

Empresas que optam por esse modelo de unidade de água gelada têm à disposição um sistema robusto que melhora a qualidade dos processos industriais e reduz custos operacionais.

Benefícios

Investir em um chiller para resfriamento de água Metalplan traz inúmeros benefícios:

- Precisão no controle térmico, vital para manter a qualidade dos produtos.

- O sistema de refrigeração chiller contribui para a eficiência energética, reduzindo o consumo de energia em comparação com métodos tradicionais.

- A central de água gelada evita flutuações térmicas que podem comprometer o desempenho das máquinas.

- Flexibilidade, já que o equipamento pode ser customizado para atender necessidades específicas.

- Sua operação silenciosa, aliada à alta durabilidade dos principais componentes, como condensador e evaporador, assegura confiabilidade operacional e longa vida útil ao equipamento.

Desempenho

A linha Polar se destaca por ter equipamentos com desempenho superior. O compressor frigorífico scroll proporciona operação silenciosa e livre de vibração, com eficiência volumétrica próxima de 100%. Já a válvula de expansão eletrônica permite um controle preciso do fluxo refrigerante, proporcionando grande economia de energia.

O controle térmico com precisão de 0,1°C, assegura estabilidade em qualquer aplicação.

Outro diferencial é o evaporador em inox, que evita corrosão e garante trocas térmicas eficientes.

Por fim, o uso de ventiladores ultrassilenciosos e reservatórios livres de corrosão assegura uma operação confiável e de longa vida útil.

Versatilidade para Diversas Aplicações Industriais

A flexibilidade do chiller água permite seu uso em múltiplas indústrias. No setor plástico, é ideal para processos de injeção, sopro, laminação e termoformagem.

Já em indústrias alimentícias, a unidade de água gelada é usada para conservar alimentos e bebidas, mantendo temperaturas adequadas durante a produção.

Na metalurgia, o chiller resfriador é indispensável para máquinas de corte e solda. Outros segmentos, como farmacêutico e químico, também utilizam o sistema de refrigeração chiller para resfriar reatores e equipamentos sensíveis.

Sua ampla gama de capacidades, de 1.000 a 720.000 kcal/h, e a possibilidade de personalização tornam o chiller de água gelada uma solução versátil e indispensável.

Durabilidade e Performance

A robustez do Polar reflete sua engenharia de ponta. Fabricados no Brasil, seus componentes como o reservatório 100% em alumínio e o gabinete em inox (opcional) garantem resistência à corrosão e maior durabilidade, mesmo em condições extremas.

O condensador microcanal em alumínio brasado é projetado para suportar altas temperaturas. Já a bomba d’água conta com projeto simples e alta tecnologia incorporada, além de ser compacta.

Assim, o equipamento combina confiabilidade operacional com custos reduzidos, mantendo desempenho constante ao longo do tempo.

Eficiência Energética

A eficiência energética é um dos pilares do sistema de refrigeração chiller Polar. Sua válvula de expansão eletrônica otimiza o uso de refrigerante, reduzindo o consumo de energia.

Já os ventiladores ultrassilenciosos têm nível de ruído 60% inferior aos modelos convencionais, com alta vazão e baixo consumo energético.

O painel Mastercontrol permite controle e monitoramento inteligente das principais funções, como desligamento automático dos compressores frigoríficos, gerando economia significativa.

Com a certificação ISO 50001, a Metalplan reafirma seu compromisso com práticas sustentáveis, garantindo que o chiller água gelada seja uma solução eficiente para empresas que desejam aliar performance à preservação ambiental.

Perguntas Frequentes sobre Chiller de Água Gelada e Outros Fluidos | Polar

nossos engenheiros

aguardam seu contato

nossos engenheiros

aguardam seu contato

Produtos

Ar comprimido

Compressores de Ar

- Compressor de parafuso | Rotor Plus (4 a 25 hp)

- Compressor de parafuso | TotalPack Flex (10 a 250 hp)

- Compressor isento de óleo (scroll) | ScrollTech Zero Oil Free (5 a 50 hp)

- BOOSTER ISENTO DE ÓLEO (PISTÃO)/COMPRESSOR DE ALTA PRESSÃO (ATÉ 40 BAR)

- BOOSTER LUBRIFICADO (PISTÃO)/COMPRESSOR DE ALTA PRESSÃO (ATÉ 40 BAR)

- Gerenciamento eletrônico de compressores

Secadores de ar comprimido

- Secadores por absorção | DewDrop (6 a 32 pcm)

- Secador por refrigeração com filtros integrados | Titan Plus (20* a 250 pcm)

- Secador por refrigeração com filtros integrados | Energy Plus (250 a 9600 pcm)

- Secador por adsorção | Hybrid (15 a 20000 pcm)

Filtros e purificadores

- Filtros coalescentes, adsorvedores e microbiológicos | Hyperfilter

- Módulo ISO Classe Zero / ar isento de óleo | ModuCarb

- Ar comprimido para respiração humana | Inspire

- Purificador de ar comprimido odontológico | Dental Air Purifier

Reservatórios de ar comprimido

Redes de ar comprimido em alumínio

Purgadores automáticos

- Purgador eletrônico digital temporizado | Cronomatic

- Purgador magnético de bóia | Zeromatic

- Dreno pescador | Easy Drain

Tratamento de condensado

Elementos filtrantes premium

Lubrificantes

- Óleo 100% sintético para compressores de ar | Rotor Oil Extra EcoBlue

- Óleo 100% sintético FOOD GRADE para compressores de ar | Rotor Oil Extra Food Grade

Materiais adsorvedores / absorvedores

ar comprimido

Geradores de nitrogênio on site

- Gerador de nitrogênio gasoso on site (industrial) | NitroMax

- Gerador de nitrogênio gasoso on site (automotivo) | NitroMax Tyre

Geradores de oxigênio on site

- Gerador de oxigênio gasoso on site (industrial) | OxiPlus

- Gerador de oxigênio gasoso on site (hospitalar) | OxiPlus Med

REFRIGERAÇÃO INDUSTRIAL

BIOGÁS & GNV

- COMPRESSOR DE PARAFUSO LUBRIFICADO PARA BIOGÁS | POWERPACK | ATÉ 3000 M³/H

- COMPRESSOR DE PISTÃO COM OU SEM LUBRIFICAÇÃO PARA BIOMETANO | DA 300 M | ATÉ 6000 M³/H

- COMPRESSOR DE PISTÃO COM OU SEM LUBRIFICAÇÃO PARA BIOMETANO/GNV | SA 200 M | ATÉ 6000 M³/H

- ESTAÇÃO INTEGRADA DE COMPRESSÃO & PURIFICAÇÃO | UPGRADING DE BIOGÁS EM BIOMETANO

entre em contato

R. Fernão Dias, 14 – Cajamar – São Paulo –

Brasil – 07790-560

Telefone: +55 11 4448-6900

E-mail: metalplan@metalplan.com.br

Horário de Atendimento

Segunda a quinta-feira: 8h às 18h

Sexta-feira: 8h às 17h

Horário de Expedição (Coletas por Transportadoras)

Segunda a quinta-feira: 8h às 16h45

Sexta-feira: 8h às 15h45

Intervalo para almoço: das 11h20 às 12h40

redes sociais

Todos os direitos reservados | Política de privacidade

Desenvolvido por Agência de Marketing B2B e Marketing Industrial